Thrusters, CPP & Stern Tube Seals

One call for all your propulsion services

PROPULSION

Reliable Propulsion Service Partner

We, we are proud to provide exceptional propulsion services that aim to improve the reliability of your ships. Our focus is on offering comprehensive maintenance solutions, including thruster repair, major overhauls, and inspections, seal bonding & CPP Overhauls.

Our team of propulsion engineers is experienced in handling maintenance, overhauls, and repairs for all makes and types of thrusters CPP Or FPP, whether in dock or afloat.

We can provide the following marine thruster service and repair options

Inspection On The Dock

- Backlash and tooth pattern verification

- Trust bearing clearance verification on pinion and propeller shaft.

- Propeller blades seals exchange

- Propeller shaft seals exchange

- Functional test

Inspection On The Water

- Backlash verification

- Pitch adjustments

- Thrust bearing clearance verification on pinion shaft

General Overhaul

- Thruster removal from the tunnel

- Overhaul in the workshop

- Parts verification

- Machining if necessary

- Backlash and pattern adjustments

- Thruster installation in the tunnel

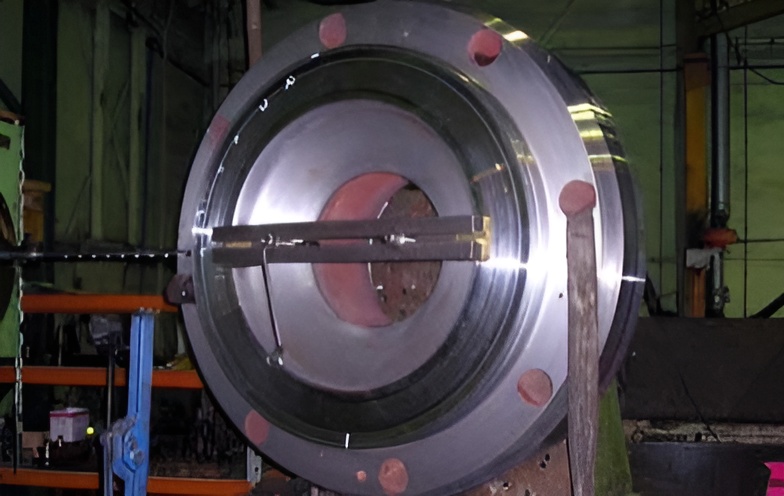

CPP Repairs

Our engineers can inspect, check, maintain and repair any or all of your CPP system. We can work on CPP units afloat, but we can also work at the shipyard or in our own fully equipped workshop if needed.

Our expertise includes:

- Shaft

- Blades

- Hub

- OD-box

- Coupling

- Power pack

Our Stern Tube Seal Services

- Complete seal housing overhaul

- In-situ bonding

- Liner inspection and machining

- Liner alignment

We Are Specialists In The Service And Repair Of The Following Makes Of Marine Thruster & Cpp’s

Additionally Specialising In (Independent Of Original Equipment Manufacturer)

- Berg Authorized Service Partner

- Kawasaki

- Kongsberg / Aquamaster / Rolls-Royce

- Brunvoll

- ZF / HRP

- Thrustmaster

- Niigata

- Kamome

Stern tube seal spare parts

- Genuine OEM seals

- After market seals

- After market seals

- Liners

If you would like to talk to one of our team about your marine thruster servicing or repair requirements then please feel free to get in touch.

Why Buy Spare Parts From WAPSGLOBAL?

Genuine OEM & High-Quality After Market Spare Parts

Quick Turnaround Time For Delivery

Strong Technical Support Through In-House Expertise

Emergency Spares Availability (Strategic stock worldwide)

Prompt Support