Electric Motor Overhaul & Repairs

Motor Overhaul

A sample overhaul work scope includes –

- Collection from site.

- Inspect and record all relevant data from the nameplate.

- Carry out electrical and mechanical check tests to verify motor condition and any reported faults, where possible.

- Dismantle motor.

- Clean and inspect all component parts .

- Datum checks, including bearing journals and seatings, shaft extensions, shaft extension run out, shaft seal fits, commutator diameter, and brush surface length .

- Repair or replacement of defect components and parts.

- Steam cleaning, stove drying and varnishing of stator and rotor windings as specified in IEEE 1068.

- Rotating parts dynamically balanced to ISO grade 2.5 or better.

- Up to date motor plate fitted before dispatch.

- Delivery to customer site and recomissioning.

Motor Cleaning & Restoration

With Dry Ice Blasting you can avoid any drying time delays, avoid clean up and increase the reliability of your electrical equipment. Dry Ice Blasting is a completely “dry” cleaning process that is non-damaging and used efficiently on stationary and rotating electrical equipment. Because Dry Ice converts to gas there is no fluid or water residue. As a result, there is no disassembling of electrical components or equipment.

Motor Parts That We Clean:

- Switch Gears

- Turbines

- Windings

- Transformers

- Substations

- Line insulators

- Compressors and generators

- AC/DC motors

- Circuit breakers

- Rotors

- Stators

- Field frames

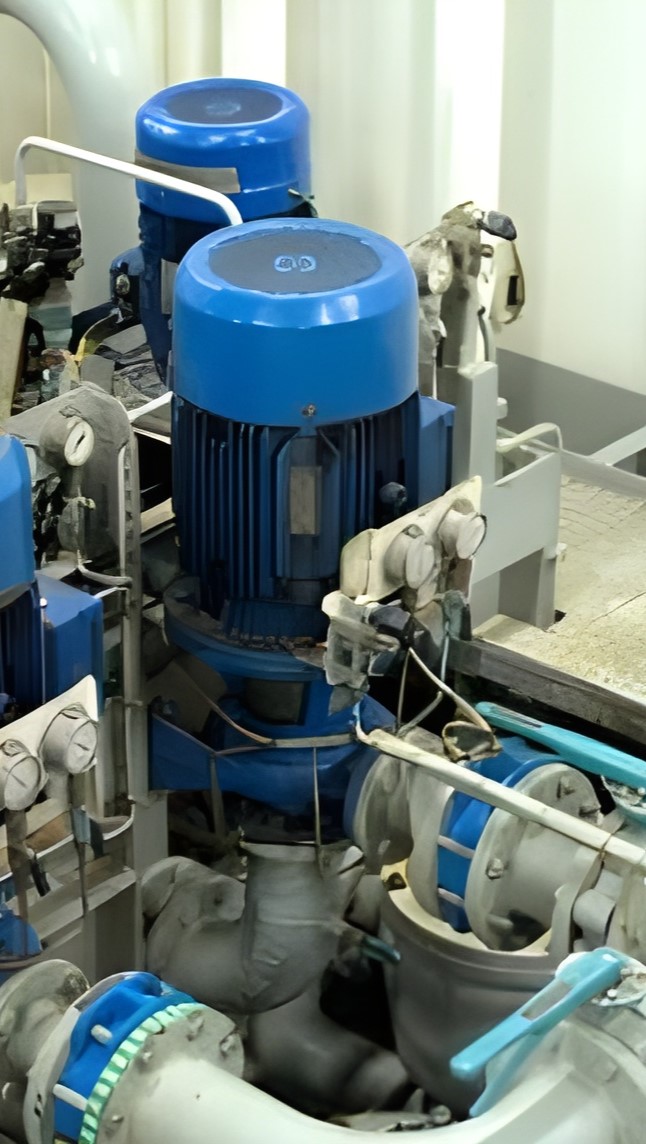

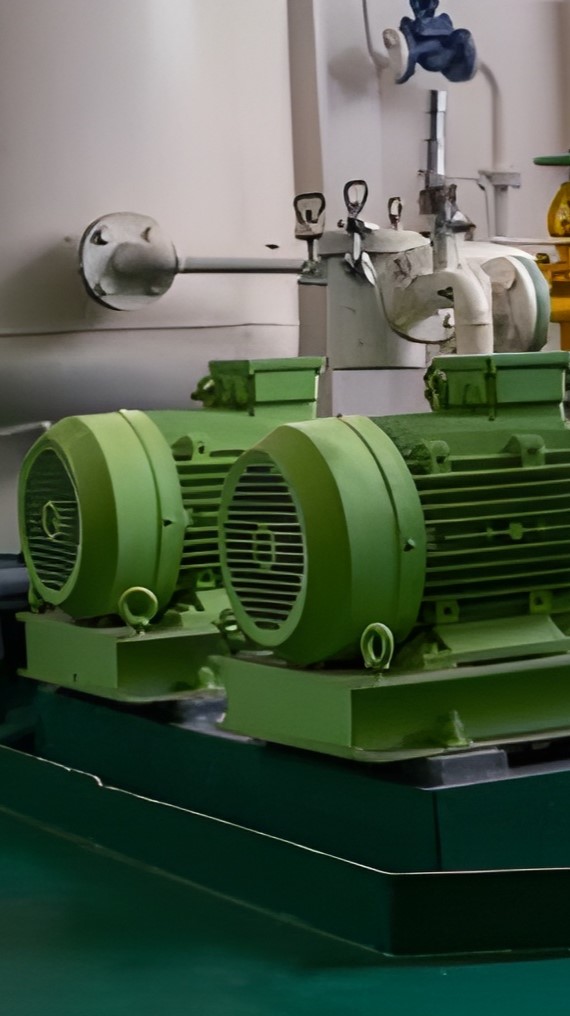

Rotating Equipment Repairs

Motor rewinds need to be done quickly and at a moment’s notice,which is why our team of engineers are at your service 24 hours a day, seven days a week. We’re constantly investing in training our engineers and you can reap the benefits of our market-leading offering. Our in-house team are multi-skilled, enabling them to carry out all manner of repairs in our Electro-Mechanical workshop.

Dry Ice Blasting

Dry ice blasting is a safe cleaning method for sensitive electrical components. It does not cause damage to the equipment due to dry ice’s non-abrasive properties. Dry ice blasting is possible when equipment is operational reducing production downtime. ICEsonic dry ice blasting system does not require additional chemicals and does not create secondary waste.

Dry ice cleaning is a revolutionary cleaning technology that involves the acceleration of dry ice (CO2) pellets in a pressurised jet air stream at the speed of sound, to impact a substrate requiring cleaning. Dry ice pellets are a solid form of Carbon Dioxide (CO2), which is at a temperature of -78.5°C, with a 3mm diameter. The dry ice pellets are inert (non-combustible), non-flammable, non-conductive (making it electrically safe), odourless and non-toxic and is a recycled man-made bi-product of hydrocarbon and ammonia production.

Dry Ice Cleaning

Dry Ice Cleaning as Industrial Cleaning Solutions

- Dry Ice cleaning is known by several names: Dry Ice blasting, Dry Ice cleaning, CO2 blasting, and even environmentally sustainable cleaning.

- Dry Ice cleaning is an efficient and cost-effective industrial cleaning system, which helps industries to maximise production capability and quality.

- Dry Ice cleaning or blasting is similar to sand blasting, plastic bead blasting or soda blasting, where particles are accelerated in a pressurised air stream to impact a surface which needs to be cleaned or prepared. But that's where the similarity ends.

- Instead of using hard abrasive particles to attack a surface (and damage it), Dry Ice blasting uses soft Dry Ice pellets accelerated to supersonic speeds, and creates mini-explosions on the surface to lift the undesirable layer off the underlying substrate.

- Dry Ice pellets can be made on site or supplied by ACP.

- No damage to the substrate.

- High degree of cleaning with no residue.

- It generates no waste stream

- It is 100% carbon neutral and environmentally friendly .

- It is completely dust free and moisture free.

- It sterilises the substrate during the cleaning action.

- Cleaning of plant and equipment is undertaken in-situ.

About Dry Ice Cleaning

- It is a non-abrasive, non-flammable and non-conductive cleaning methodntally sustainable cleaning.

- It is environmentally responsible and contains no secondary contaminants such as solvents or grit.

- It is clean and approved for use in the food industry.

- It allows most items to be cleaned in situ without time consuming disassembly.

- It can be used without damaging active electrical or mechanical parts or creating fire hazards.

- It can be used to remove production residue, release agents, contaminants, paints, oils and biofilms.

- It can be as gentle as dusting smoke damage from books or as aggressive as removing weld slag from tooling.

- It can be used for many general cleaning applications.

- is a non-toxic, liquefied gas.

- is inexpensive.

- can be stored easily at work sites

Process

- Kinetic Effect: Impact Flushing Action of Dry Ice Particles Uses kinetic energy and sublimates on impact.

- Thermal Effect: On impact the impurities on the surface cool down tremendously, shrink and loosen from the surface. Surface temperatures may fall below the freeze point of the impurities, causing the impurities to lose adhesion.

- Sublimation Effect: When dry ice particles strike the surface, they immediately phase from solid into gas. The effect increases the gas volume approximately 800 times. The sudden increase in volume assists in moving the brittle fragments of impurities away from the surface.

Dry Ice Cleaning Advantages and Uses

- No damage to the substrate

- High degree of cleaning with no residue

- It generates no waste stream

- It is 100% carbon neutral and environmentally friendly

- It is completely dust free and moisture free

- Cleaning of plant and equipment is undertaken in-situ

- Compressors and pumps

- Extraction equipment

- Electric motors

- Generators

- Pressure, production and storage vessels

- Pipelines